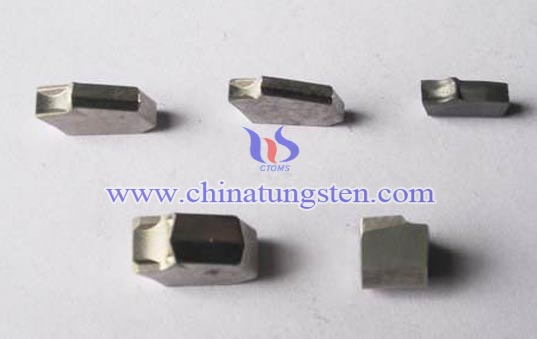

tungsten carbide indexable inserts chipbreakers

Tungsten carbide indexable inserts is an advanced structure, high cutting efficiency, with high precision and good interchangeability inserts. Tungsten carbide indexable inserts according to the processing range is divided into three series: roughing, semi-finishing and finishing, and according to the shape into different varieties: diamond, square, triangle, etc.

With the development of automated processing of tungsten carbide indexable inserts fragment crumbs increasingly high performance requirements, chipbreaker geometry is also more complex. Initially, people just on the blade grinding out a simple chip-breaking groove, or impose an additional breaking means the rake face. With the improvement of powder metallurgy manufacturing technology, chip-breaking groove in addition to straight grooves, chute, and multi-stage curve edge breaker groove, but also the emergence of small bumps, pits and grooves of various curved shapes. tungsten carbide our national standard GB2078 80 provides an indexable insert Groove A, Y, K, U, Z, V, G, E, S, H, L, M, O, D, W a total of ten five. Currently used is basically a hole and positive rake angle chip breaker groove.

Popular tungsten carbide indexable inserts chipbreakers commonly used tip geometries in the slot at the back along the bisector direction of forward projections of this design, and forward projections groove back against a large surface debris most of convex curved surface. Forward protruding part to make width narrowing at the tip, at small depths of cut, while small feed tool for improving chip breaking plays a great role. When the large depth of cut, in addition to the narrow width of the nose section, all other parts of the larger width, it will not block the chips in the breaker groove, can not flow out smoothly, resulting in excessive chip breaking, cutting force is not increase is too large. Meanwhile, anti-tank debris back surface using a convex curved design, not only can play a snap crumbs features, ease of chip curl and flow in large feeding is not easy when the phenomenon appeared in the breaker, but also enable large depths of cut chip cross-section bending, increasing the effective thickness of the chip to improve bending strength, in addition can also increase the chip side curled chip deformation increases, the chip more easily broken.