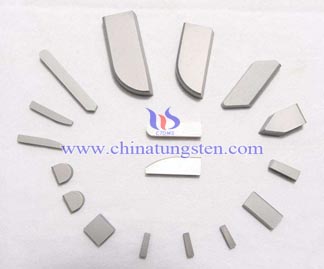

tungsten carbide fine grinding inserts

Generally the tungsten carbide inserts products into precision and general level, precision tungsten carbide inserts tolerance zone is very small, very strict, inserts have been lapping, the price is more expensive. Tungsten carbide inserts after full precision grinding, size precision can be achieved precision inserts, and the inserts edge radius decreases, the inserts surface quality improvement. Fine grinding tungsten carbide inserts relatively long life, reliability, precision cutting when the cutting depth can be made smaller.

Fine grinding tungsten carbide inserts' surface is high precision and the structure is dense, it has good wear resistance, prompting inserts wear resistance increases, so their life is also greatly improved. By improving the surface quality of the inserts after lapping, the surface roughness of machined parts to improve machining accuracy also increased, so the tungsten carbide fine grinding inserts has a good prospect. After the entire cutting process under the same conditions, no fine grinding inserts flank wear values are greater than the maximum fine grinding inserts wear by value, and the initial cutting inserts, the amount of wear of the inserts before and after fine grinding the larger the difference between the use of tungsten carbide CNC inserts after cutting through the grinding process, with different cutting parameters can be variably reduces the wear rate of tungsten carbide inserts, tungsten carbide inserts improve efficiency.

Therefore, regardless of the roughing or finishing, try using fine grinding tungsten carbide inserts. This will not only improve the precision, but also extend the life of the inserts, thus saving the cost of acquisition of the tungsten carbide inserts.