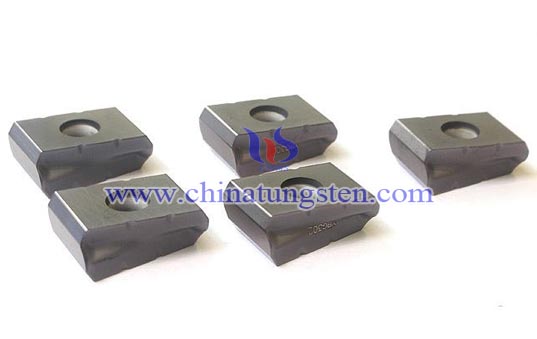

Tungsten Carbide Indexable carbide inserts

Tungsten carbide indexable carbide inserts are the industry workhorses. Even though these carbide inserts cost less than some other tools, they have the loosest tolerances, from 0 to 0.012 in., depending on the ratio of length to diameter. This means that machinists who choose carbide inserts must consider the need for a larger tolerance window and they often must be prepared to finish holes with boring tools.

Along with whole tolerances, machinists need to consider machine stability when they are selecting drill bits. Machine tool stability is essential for extending tool life and for achieving accurately drilled holes, so machinists must verify the condition of the machine spindle, fixtures and attachments.

They also should consider the inherent stability of the drill bit. For example, solid-carbide drill bits offer the best stiffness, which contributes to their high accuracy.

Tungsten Carbide Indexable carbide inserts, on the other hand, are prone to deflection. While these drills are fitted with two cutting carbide inserts — one inboard insert for the center and one from the inboard insert out to the full diameter — initially, only one of the carbide inserts will enter the cut. This creates an unstable situation that causes the drill body to deflect. Longer the drill, greater the deflection that can be caused. Therefore, machinists who use indexable carbide inserts and drill to four times diameter and higher should consider reducing feed during the first millimeter of depth and then increase to the normal federate.