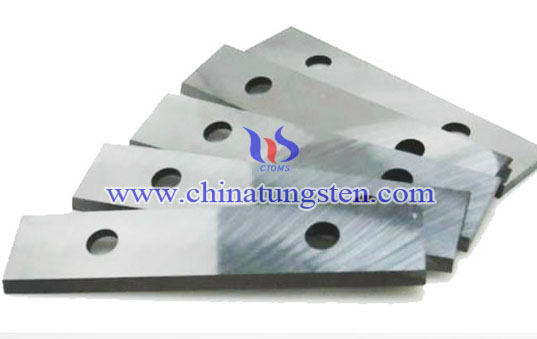

Tungsten Carbide Inserts

General knowledge of tungsten carbide inserts:

Tungsten carbide, also known as cemented carbide, is a relatively precious material which is critical to many manufacturing processes. Most metal machining processes use tungsten carbide inserts as tool tips, as cemented carbide has excellent hardness and heat resistance properties ideal for drilling, boring, shaping and forming metal workpieces. Most modern face mills, lathe tools and end mills use these cutting tools.

The only downside of using carbide inserts for such a wide range of machining processes is that the tungsten material used in creating tungsten carbide alloys is both scarce and expensive. With most tungsten reserves in the US and other Western countries exhausted, China supplies over 80% of the tungsten used worldwide. In 2005, the International Tungsten Industry Association estimated that at the current rate of global consumption, all tungsten reserves will be used up within 140 years. Tungsten carbide inserts are typically treated as disposable materials, even though only the cutting edges of the inserts are worn when they're disposed.