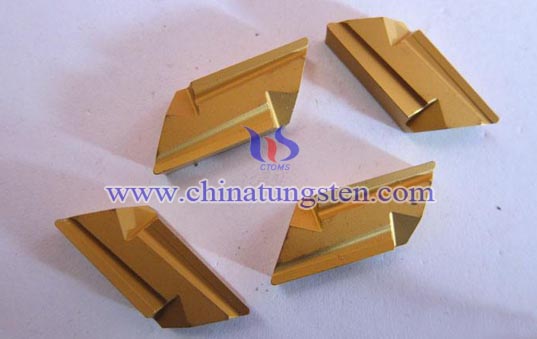

tungsten carbide inserts pressing technology

With the rapid development of manufacturing, automotive, aerospace and die industry and other key sectors of continuously put forward higher requirements the cutting, and CNC machine tools, machining centers and other advanced equipment toward to high-speed direction. At the same time, the shape of the workpiece is also more complex, requiring more precision and surface finish high, resulting in the field of metal cutting tungsten carbide inserts dimensional accuracy made increasing demands.

In addition to the continuous improvement of the powder forming apparatus to improve the accuracy of the compacts, the tungsten carbide inserts primarily by the dimensional accuracy of the grinding process control, which not only lead to waste of material, and resulting in the production process of the blade length, higher production costs. Therefore, precision press technology to produce high dimensional accuracy inserts blanks, reduce grinding allowance, help reduce production costs, shorten production cycle CNC inserts, improve production efficiency.

Affect the quality of pressing a mixture of the three elements, die and press quality. First, tungsten carbide inserts pressing process, the requirements of quality mixture with particles of uniform crumb structure and appropriate liquidity and repressive, thus ensuring the normal repression. If the mixture of filler and uniform flow of these two factors is changed, it will affect the final sintered compact density and reduced dimensional stability. Secondly, the use of high precision, smooth, efficient presses, beneficial to obtain uniform density, size and accurate pressure products. Furthermore, the stamper quality directly affect the quality of compression products, production of tungsten carbide inserts requires not only high-precision presses, precision die at the same time there must be, in the production line by the introduction of complete sets, and more functional, high-precision mold manufacturing equipment and advanced production technology and its corresponding mold testing tools and instruments, and strictly control the manufacture of precision molds, thus improving the quality of tungsten carbide inserts.