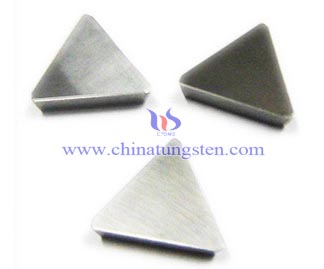

The Manufacturing Process of Tungsten Carbide Insert

Tungsten carbide insert engineer has determined what level of hardness needs to be achieved; the manufacturing process starts with powdered raw materials. Powdered tungsten, cobalt and carbon are milled and blended together with alcohol and water, creating thick slurry. This substance is put into a dryer, which evaporates the liquids, leaving a thoroughly mixed powder. Carbide inserts then undergo a sintering process in which they are mixed with a polymer to form a paste, pressed into insert-shaped dies and placed in a high-heat furnace to be sintered. The polymer is melted out of the inserts during this step, and the inserts shrink.